1947 – 2022 Self-Propelled Combines

Feeding the World

The development of the self-propelled combine harvester has changed the way the world feeds itself. Today, John Deere combines harvest more than half the world’s grain. The story of their success, from the Model 55 to the X-Series, is one of technical innovation as well as high quality customer support through a network of professional dealers.

1954 Hillside Combine

The self-levelling 55H built on John Deere’s expertise in hillside combines which started with the horse drawn model 36B in 1936. Marketing films promoted many features today’s drivers would recognise: ‘one finger’ power steering, powerful disc brakes and variable speed ground drive.

1963 Tracks

Early tracks were developed from construction machinery. Their steel plates required regular greasing and road speeds were slow. Here they are being used for rice harvesting in Italy. Sharing the familiar triangular profile of today’s tracks, it would take more than 40 years before reliable rubber tracks would become available.

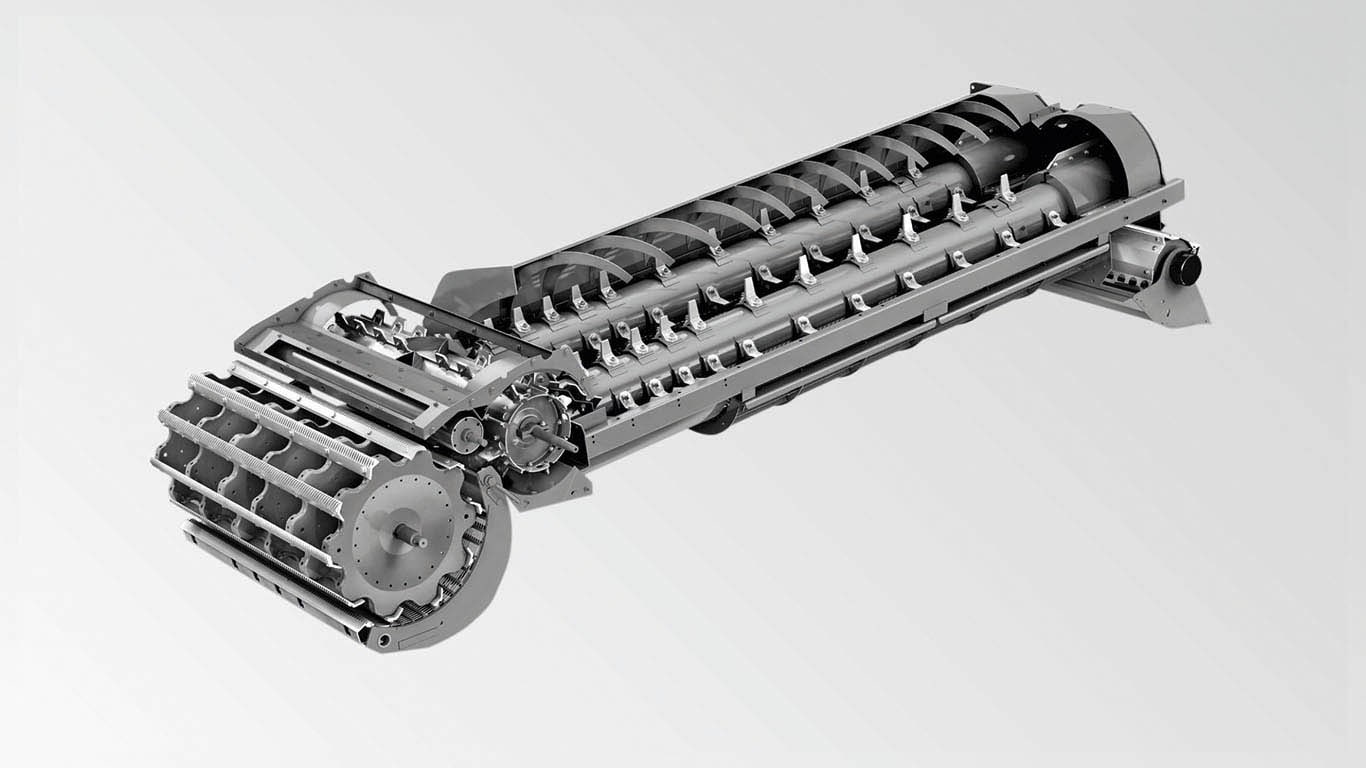

1992 World’s first hybrid combine

The CTS (Cylinder Tine Separator) combine featured a large cylinder and concave upfront with two rotors provided a secondary threshing action. It remained the world’s only hybrid combine until 1996 when John Deere’s patent expired. The compact, narrow body provided exceptional throughput and it is still sold in Asia for rice harvesting.

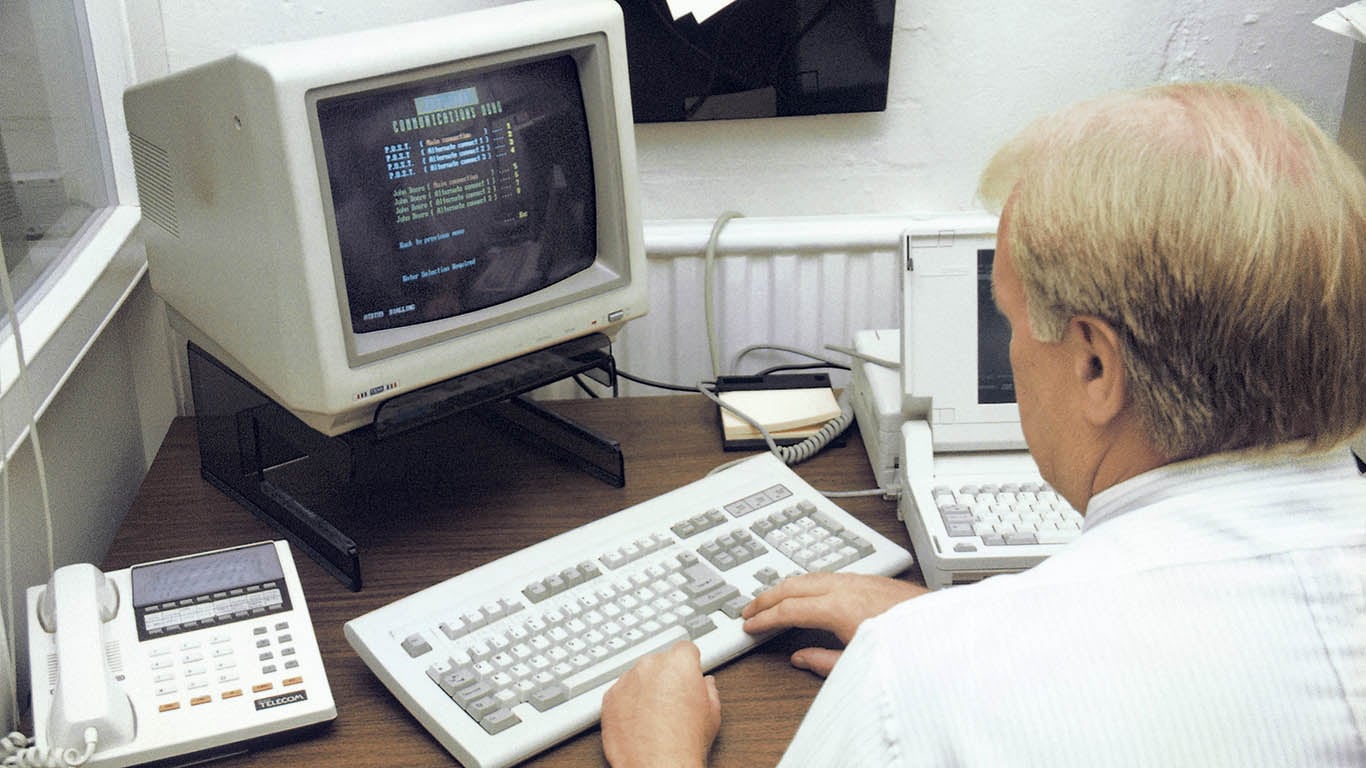

1999 Greenstar 1 Display

Featuring Parallel Tracking the driver had to concentrate hard to keep the combine on the centre line. It wasn’t until AutoTrac in 2002 that true hands-free guidance arrived. The display also featured Harvest Monitor and Yield Mapping software and many are still in use today.

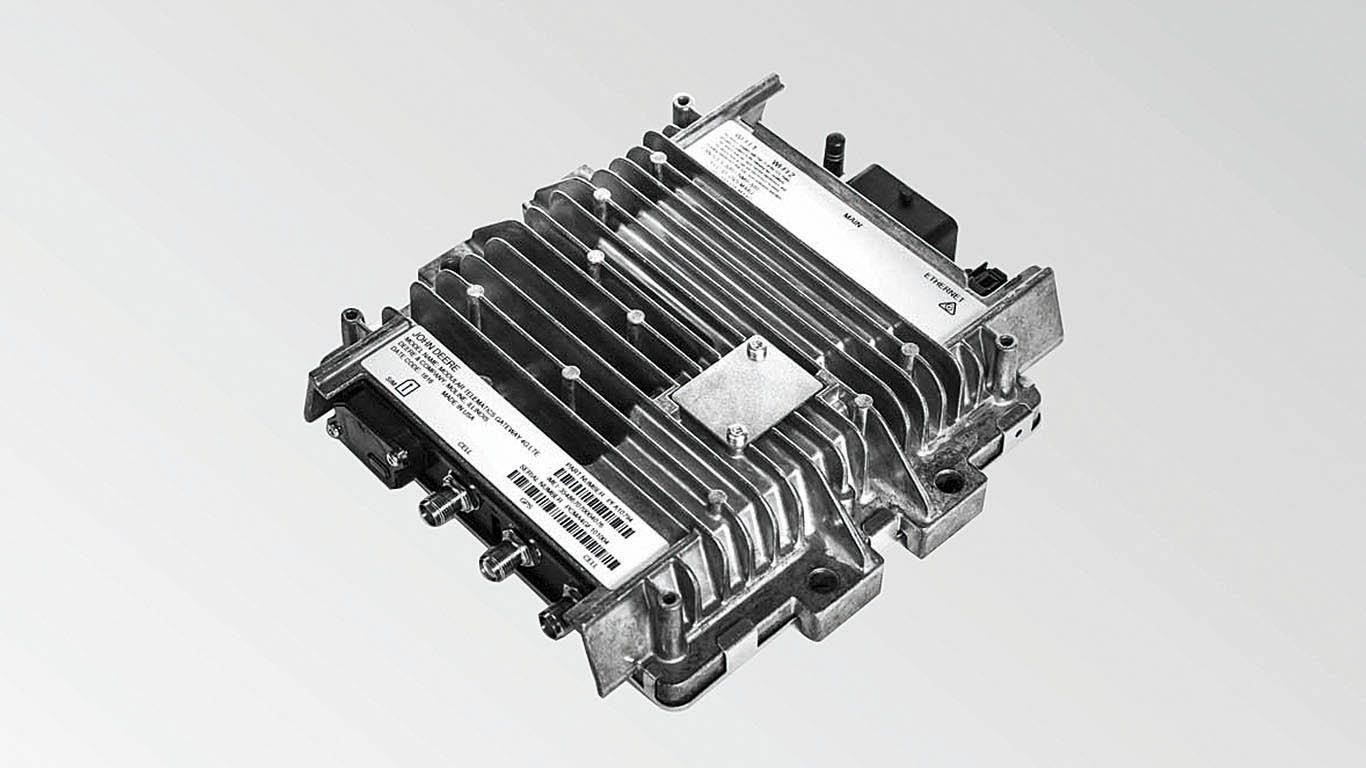

2002 Machine Connectivity

Early combine fleets used flags to signal which combine needed unloading. Then came short wave radio and mobile phones. The introduction of onboard electronics to enable JDLink machine connectivity is the biggest harvesting innovation of the past 20 years. Transmitting real-time data on machine performance and positioning for remote monitoring, it’s transforming work planning, harvest logistics and more.

2010 500,000th Combine

Greg Briggs from Cisco, Illinois took delivery of the 500,000th John Deere combine, a 9870 STS on 20th May 2010. The Single Tine Separator System was a major departure from the traditional walker system and is so successful it lives on today in the S-Series combines - the world’s most popular combine.

1997 John Deere Financial in Europe

Finance has been extremely important ever since the Great Depression in the 1930s when John Deere extended credit terms to struggling farmers. In later years, with the creation of John Deere Financial in the UK in 1997, a foothold in Europe was established and more flexible financing options have become available to meet the challenges of individual farmers.

Fast forward to the future

Find out what an upgrade to our latest combines can do for you.

6R Utility Tractors

Premium Performance

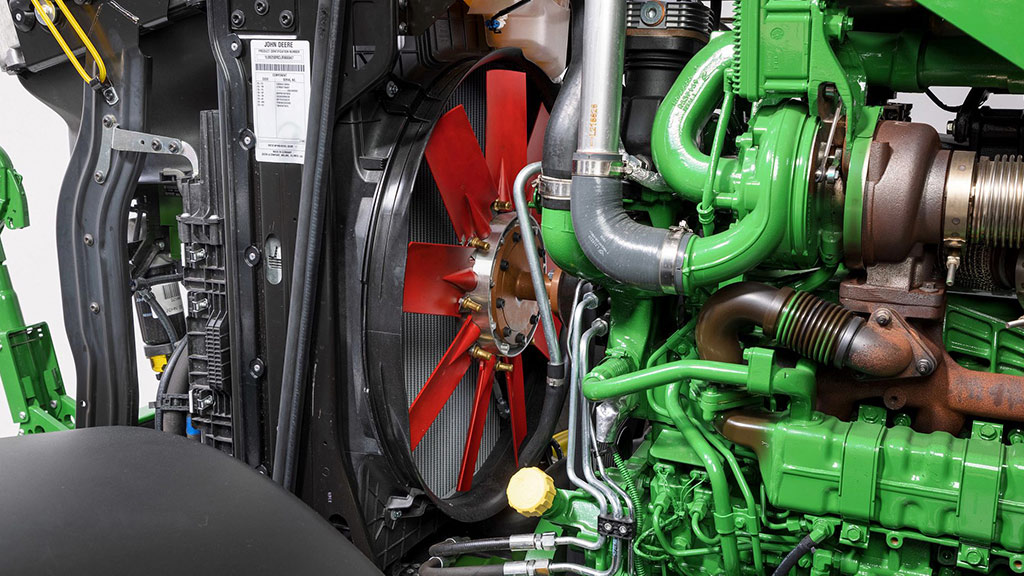

Get the power, reliability & efficiency you need with John Deere 6R Utility Tractors. Improve productivity with the power-to-weight ratio and a power boost when you need it. Improve engine cooling performance, thanks to the reversible fan letting you keep radiator screens clear of chaff and debris. Receive real-time information with new loader technology, like dynamic weighing. Enjoy a premium ride with the comfortable cab with better visibility, ergonomic controls and a smooth ride in the John Deere 6R.

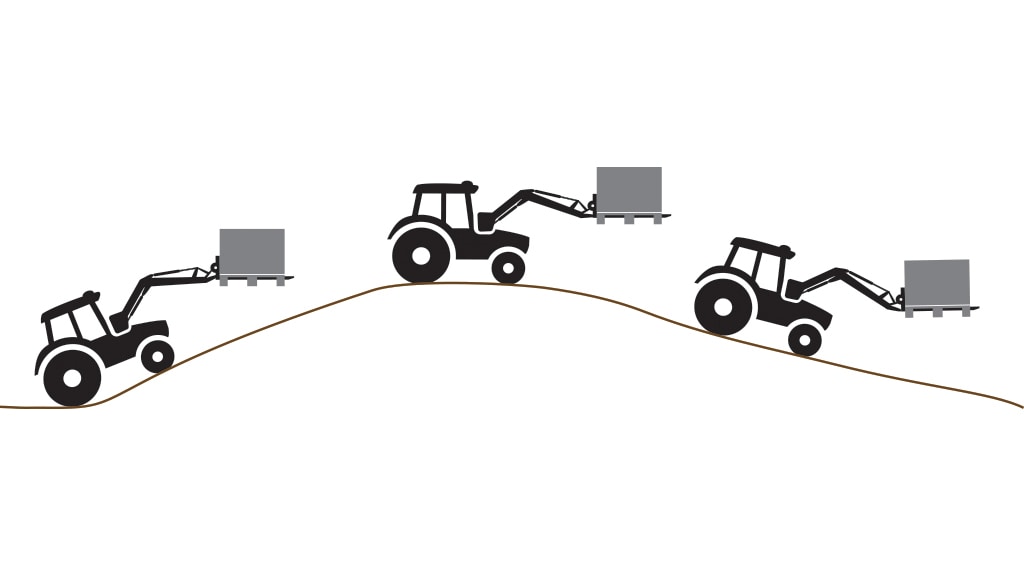

Loader Technology

Mixing feed, weighing bales and loading goods have never been easier with new loader technologies on the John Deere 6R Tractors.

Connected Technology

The John Deere 6R Tractors are among the smartest tractors ever built, featuring a wide variety of John Deere Precision Ag Technologies.

Compare our 6R Utility Tractors

| Model | Engine HP | PTO HP | Transmission | Hydraulics | Cab or Open Station | Loader Compatibility |

|---|---|---|---|---|---|---|

|

Engine HP: 121 HP Max/110 HP Rated with up to 20 additional HP (IPM) |

86 hp (64 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) |

Cab |

620R or 640R |

|

|

Engine HP: 132 HP Max/120 HP Rated with up to 20 additional HP (IPM) |

94 hp (70 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) |

Cab |

620R or 640R |

|

|

Engine HP: 143 HP Max/130 HP Rated with up to 20 additional HP (IPM) |

101 hp (75 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

620R or 640R |

|

|

Engine HP: 154 HP Max/140 HP Rated with up to 20 additional HP (IPM) |

110 hp (82 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

620R or 640R |

|

|

Engine HP: 160 HP Max/145 HP Rated with up to 40 additional HP (IPM) |

111 hp (83 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h, 24-speed Direct Drive 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

640R or 660R |

|

|

Engine HP: 171 HP Max/155 HP Rated with up to 40 additional HP (IPM) |

121 hp (90 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h, 24-speed Direct Drive 40 km/h and 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

640R or 660R |

|

|

Engine HP: 182 HP Max/165 HP Rated with up to 40 additional HP (IPM) |

129 hp (96 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h |

Standard: 45 cc pump: 30 gpm (114 L/min) Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

640R or 660R |

|

|

Engine HP: 193 HP Max/175 HP Rated with up to 40 additional HP (IPM) |

140 hp (104 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h, 24-speed Direct Drive 40 km/h and 50 km/h |

Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

660R or 680R |

|

|

Engine HP: 215 HP Max/195 HP Rated with up to 40 additional HP (IPM) |

160 hp (119 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h, 24-speed Direct Drive 40 km/h and 50 km/h |

Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

660R or 680R |

|

|

Engine HP: 237 HP Max/215 HP Rated with up to 40 additional HP (IPM) |

178 hp (133 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h, 24-speed AutoQuad™ PLUS ECO 40 km/h and 50 km/h, 24-speed Direct Drive 40 km/h and 50 km/h |

Optional: 60 cc pump 41 gpm (155 L/min) |

Cab |

660R or 680R |

|

|

Engine HP: 253 HP Max/230 HP Rated with up to 40 additional HP (IPM) |

185 hp (136 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h |

Standard: 85 cc pump 42 gpm (160 L/min) |

Cab |

680R |

|

|

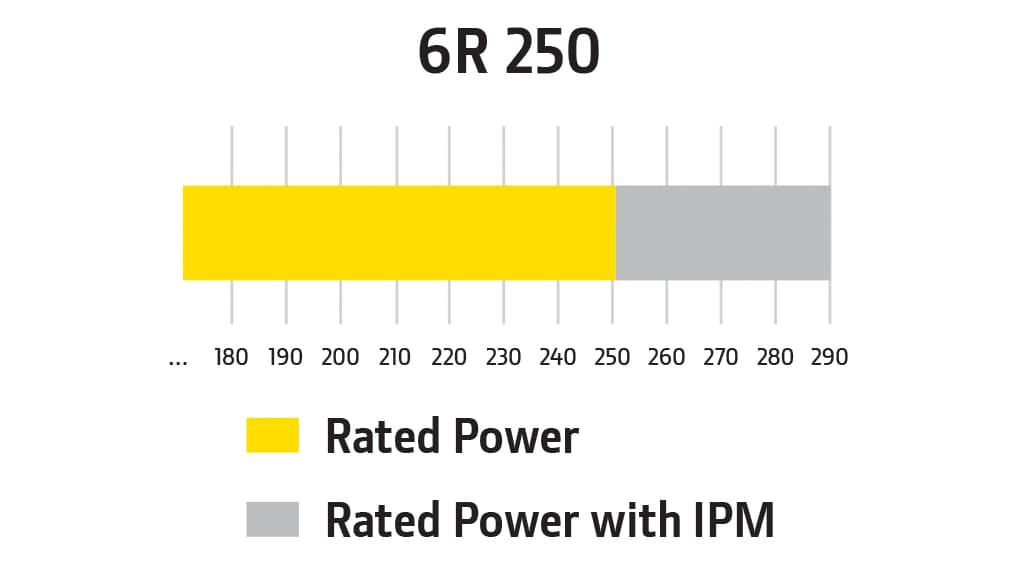

Engine HP: 275 HP Max/250 HP Rated with up to 40 additional HP (IPM) |

203 hp (149 kW) |

Standard: Infinitely variable transmission (IVT™) 40 km/h, Optional: IVT 50 km/h |

Standard: 85 cc pump 42 gpm (160 L/min) |

Cab |

680R |

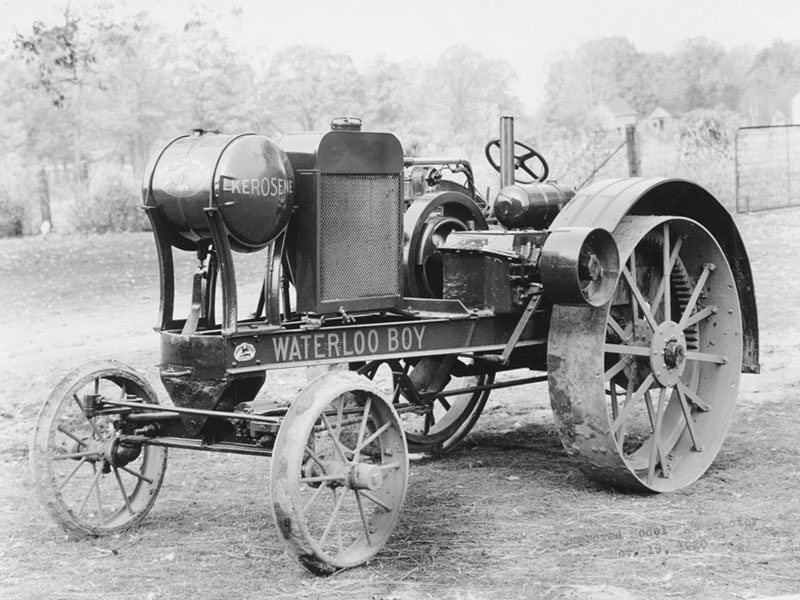

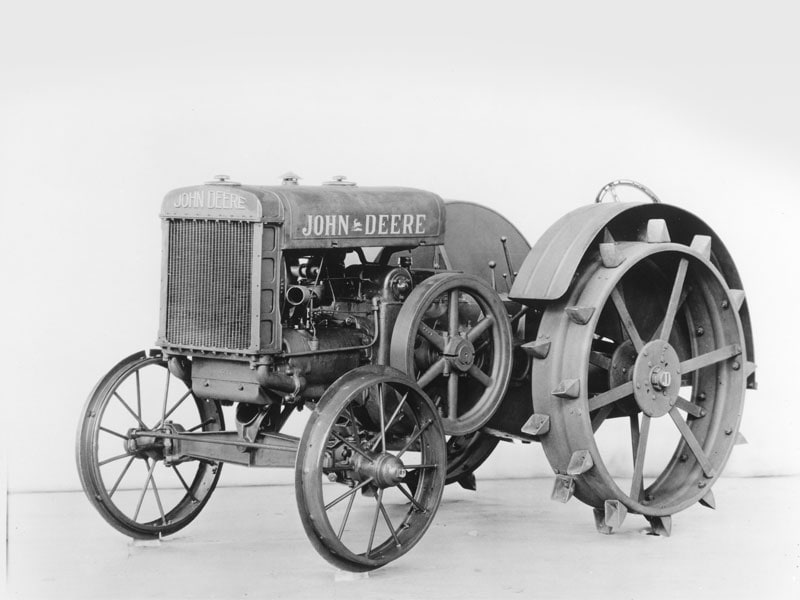

PRIDE IN OUR HISTORY.

INSPIRATION FOR THE FUTURE.

Milestones In Tractor Production

From the 27hp Waterloo Boy, the first tractor built and marketed by John Deere, to an all-round champion 670hp machine, all in 100 years. Staying true to our core values of integrity, quality, commitment and innovation, we will take decisive steps to shape our future. We’re working full throttle so that we can continue to offer first-rate solutions to our customers around the world during the next 100 years. Because our passion lies in all things towing, tilling, ploughing and growing.

History

From the Waterloo Boy to the John Deere 6250R: 36 major models and series from the last 100 years.

Our pre-threshing cylinder (PTC) brings a big advantage, especially in tough high-yielding conditions. The reduced angle between feederhouse and threshing concave accelerates, pre-threshes and smooths the crop flow to improve separation. Grain quality is assured by the paddle design. The load on the main concave is reduced, resulting in up to 20% performance increase.

PowerGard

Experience the PowerGard feeling and find out more about equipment and parts warranty

FarmSight Services

FarmSight Services packages deliver uptime, productivity and performance

Parts & Services

See what’s right for you

Productivity solutions matched to the lifecycle stage of your machines.

1-3 Years

Your new machine – protect it

When you buy a new machine, there are some excellent ways to protect your investment..

3-7 Years

Your mid-life machine – update it

Keep your machine running at peak performance, with steady uptime.

>7 Years

Your mature machine – renew it

Keep your trusted machine operating safely, reliably and cost-effectively with these great options.

HARVEST PROMISE

BACK-UP WHEN YOU NEED IT. GUARANTEED

EXPERT CHECK

The Expert Check optimises your combine ready for the next harvest season. Our specially trained and certified Inspection Experts know which components require special attention – thanks to John Deere’s sophisticated tools developed from knowledge gathered from thousands of harvests.

24 HOUR PARTS PROMISE

We’ve invested in the biggest parts logistics network in the agriculture business. And with more machines in the field than any other manufacturer we hold more parts stock than anyone else. It all means we consistently deliver more than 97% of all orders within 24 hours.

BACK-UP MACHINE

We will provide a back-up machine if parts are delivered late. The difference is that we’ll take care of everything, not just pay a contractor. Our dealers have the right combines with the right size in reserve.

TRAINING

Factory trained experts at Certified dealers will provide professional driving training not just when you take delivery of your new combine, but they will be on-hand for refresher courses season after season.

EXPERTS IN PLACE

Certified dealers have full-time, factory trained harvesting experts to set up your combine prior to the season. They’ll also visit you during the season to make sure your machine is always running at the optimum performance level.

*Eligible are all John Deere combines max. 7 years old, maintained in line with operator’s manual utilizing genuine parts only and EXPERT CHECK after season assessment with carried out subsequent repair work as recommended.

6R Series

Now with CommandPRO

GENIUS: THE ALL NEW COMMANDPRO JOYSTICK

There’s never been a better way to control a tractor. Top speed reached with just one push and 11 reconfigurable buttons - the new CommandPRO joystick introduces a new dimension of ergonomy and versatility.

Variable Ratio Steering

Much less arm movement and significantly less steering effort required on headland turns or when manoeuvring in tight spaces. Faster turning of the steering wheel increases hydraulic flow for quicker tyre response. It’s an all-around better way to steer a tractor.

ISOBUS like no other

The 6R tractor fulfills more ISOBUS AEF standards than any other tractor. From the 4200 and 4600CommandCenter you can document and do section control seamlessly. With CommandPRO you can control any ISOBUS function of your implement.

MORE POWER, CLEANER POWER

Get all the power you need with less fuel and lower emissions from our renowned 4.5 l PSS 4 cyl. engine or the 6.8 l PVS or PSS 6 cyl. engines with series turbochargers.

Model above 130 hp (rated power) have a Stage V compliant engine.

Intelligent Power Management

Intelligent Power Management (1) provides up to 40 additional hp for transport and PTO applications. max. power (2) and max. torque (3) are achieved at 1,900 and 1,600 rpm respectively to ensure optimum response with low fuel consumption levels.*

*) Graph and figures displayed are valid for 6250R. For other models please check brochure or ask your dealer.

Low running costs

With a lifetime Diesel Particle Filter, low 2-3 % DEF consumption 6R Series tractors boost your productivity while lowering your costs. Additionally, 6,8l engines feature service intervals extended to 750 hours.

STRONG AND EFFICIENT

Using the right transmission for your application profile can make life a lot easier and more productive for you. All the 6R transmissions have been designed to maximize the power output, thus the pull and efficiency.

AutoPowr

AutoPowr delivers step-less power at speeds between 50 m/h and 50 km/h. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, reducing noise and saving fuel. 50 km/h is maintained at 1630 rpm, 40 km/h at 1300 rpm with CommandPRO.

AutoPowr

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

DirectDrive

DirectDrive is an eight-speed, three-range transmission. Super-efficient dual-clutch technology always has the next gear lined up, so there’s no lost momentum when shifting. During transport, DirectDrive reduces the engine speed to 1,550 rpm at 40 km/h and 1,600 rpm at 50 km/h, thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

THE FEEL GOOD,

DO GREAT CAB

This is the roomiest cab in its class. The ComfortView cab combines ergonomic excellence and big all-round visibility and comfort for an efficient and expansive workspace where you can feel good and do great.

Generation 4 CommandCenter

The Generation 4 CommandCenter features familiar tablet-like swipe functionality and monitors all essential tractor functions. It is available in an 10” and a new 8,4” version. Always with touchscreen, AEF-ISOBUS certified and capable of doing AutoTrac, Section Control and documentation.

COMFORT FOR PRODUCTIVITY PURISTS

You’d like optimal traction, more power to the ground, and enhanced operator comfort? The 6R features TLS Plus front axle suspension, HCS Plus cab suspension and Variable Ratio Steering for less steering effort.

6R HYDRAULICS: SMART MUSCLE

Definitely located at the upper end of the performance spectrum, the hydraulic pump of the 6230R and 6250R delivers an impressive flow of 160 l/min at only 1,500 RPM.

New for the 6145R and the 6155R is the 155 l/min pump that will increase the performance in demanding hydraulic operation.

Smart control

The intuitive CommandCenter controls allow you to manage the Selective Control Vales (SCVs) on the move. The large digital display lets you monitor flow rates and times, keeping you in control of all hydraulic systems.

SCVS APLENTY

In a 6R you get up to six electro-hydraulic selective control valves (SCVs) – with pressure relief lever, logically Clustered.

6110R - 6120R - 6130R

AutoPowr delivers step-less power at speeds between 50 m/h and 50 km/h. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, reducing noise and saving fuel. 50 km/h is maintained at 1630 rpm, 40 km/h at 1300 rpm with CommandPRO.

6135R - 6145R - 6155R

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

6175R - 6195R - 6215R

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

6230R - 6250R

DirectDrive is an eight-speed, three-range transmission. Super-efficient dual-clutch technology always has the next gear lined up, so there’s no lost momentum when shifting. During transport, DirectDrive reduces the engine speed to 1,550 rpm at 40 km/h and 1,600 rpm at 50 km/h, thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

John Deere

Scarifiers

Help your lawn to grow in a healthy manner by using a scarifier to remove unwanted thatch and moss. Choose from electric or petrol machines in a variety of different sizes.

Walk Behind Mowers

A comprehensive range of walk-behind mowers means we have a walk-behind mower to match your requirements.

Riding Lawn Equipment

Designed for comfort, convenience and performance, John Deere lawn tractors are the ultimate in lawn maintenance.

Robotic Mower

Fancy a perfect lawn without the effort and discipline? TANGO E5 Series II mows in any weather and at any time – all by itself.

YOU MAY BE INTERESTED IN…

5E Series. Meet the little giant

Enjoy all-round versatility: 5E Series tractors provide John Deere dependability and performance to a wide range of applications, like arable farming, small-scale livestock, daily duties in dairy production as well as front loader works or tasks at specialized farms.

INTRODUCING THE 9000 SERIES SPFH

The 8000 Series raised the bar for quality forage harvesting – a true success story since day one. Building on that foundation and fueled by our ambition to help you produce more high-quality silage more efficiently – we present you the 9000 Series! PURE PERFORMANCE

More Videos

Our pre-threshing cylinder (PTC) brings a big advantage, especially in tough high-yielding conditions. The reduced angle between feederhouse and threshing concave accelerates, pre-threshes and smooths the crop flow to improve separation. Grain quality is assured by the paddle design. The load on the main concave is reduced, resulting in up to 20% performance increase.

John Deere

Scarifiers

Help your lawn to grow in a healthy manner by using a scarifier to remove unwanted thatch and moss. Choose from electric or petrol machines in a variety of different sizes.

Walk Behind Mowers

A comprehensive range of walk-behind mowers means we have a walk-behind mower to match your requirements.

Riding Lawn Equipment

Designed for comfort, convenience and performance, John Deere lawn tractors are the ultimate in lawn maintenance.

Robotic Mower

Fancy a perfect lawn without the effort and discipline? TANGO E5 Series II mows in any weather and at any time – all by itself.

YOU MAY BE INTERESTED IN…

5E Series. Meet the little giant

Enjoy all-round versatility: 5E Series tractors provide John Deere dependability and performance to a wide range of applications, like arable farming, small-scale livestock, daily duties in dairy production as well as front loader works or tasks at specialized farms.

INTRODUCING THE 9000 SERIES SPFH

The 8000 Series raised the bar for quality forage harvesting – a true success story since day one. Building on that foundation and fueled by our ambition to help you produce more high-quality silage more efficiently – we present you the 9000 Series! PURE PERFORMANCE

6R Series

Now with CommandPRO

GENIUS: THE ALL NEW COMMANDPRO JOYSTICK

There’s never been a better way to control a tractor. Top speed reached with just one push and 11 reconfigurable buttons - the new CommandPRO joystick introduces a new dimension of ergonomy and versatility.

Variable Ratio Steering

Much less arm movement and significantly less steering effort required on headland turns or when manoeuvring in tight spaces. Faster turning of the steering wheel increases hydraulic flow for quicker tyre response. It’s an all-around better way to steer a tractor.

ISOBUS like no other

The 6R tractor fulfills more ISOBUS AEF standards than any other tractor. From the 4200 and 4600CommandCenter you can document and do section control seamlessly. With CommandPRO you can control any ISOBUS function of your implement.

MORE POWER, CLEANER POWER

Get all the power you need with less fuel and lower emissions from our renowned 4.5 l PSS 4 cyl. engine or the 6.8 l PVS or PSS 6 cyl. engines with series turbochargers.

Model above 130 hp (rated power) have a Stage V compliant engine.

Intelligent Power Management

Intelligent Power Management (1) provides up to 40 additional hp for transport and PTO applications. max. power (2) and max. torque (3) are achieved at 1,900 and 1,600 rpm respectively to ensure optimum response with low fuel consumption levels.*

*) Graph and figures displayed are valid for 6250R. For other models please check brochure or ask your dealer.

Low running costs

With a lifetime Diesel Particle Filter, low 2-3 % DEF consumption 6R Series tractors boost your productivity while lowering your costs. Additionally, 6,8l engines feature service intervals extended to 750 hours.

STRONG AND EFFICIENT

Using the right transmission for your application profile can make life a lot easier and more productive for you. All the 6R transmissions have been designed to maximize the power output, thus the pull and efficiency.

AutoPowr

AutoPowr delivers step-less power at speeds between 50 m/h and 50 km/h. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, reducing noise and saving fuel. 50 km/h is maintained at 1630 rpm, 40 km/h at 1300 rpm with CommandPRO.

AutoPowr

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

DirectDrive

DirectDrive is an eight-speed, three-range transmission. Super-efficient dual-clutch technology always has the next gear lined up, so there’s no lost momentum when shifting. During transport, DirectDrive reduces the engine speed to 1,550 rpm at 40 km/h and 1,600 rpm at 50 km/h, thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

THE FEEL GOOD,

DO GREAT CAB

This is the roomiest cab in its class. The ComfortView cab combines ergonomic excellence and big all-round visibility and comfort for an efficient and expansive workspace where you can feel good and do great.

Generation 4 CommandCenter

The Generation 4 CommandCenter features familiar tablet-like swipe functionality and monitors all essential tractor functions. It is available in an 10” and a new 8,4” version. Always with touchscreen, AEF-ISOBUS certified and capable of doing AutoTrac, Section Control and documentation.

COMFORT FOR PRODUCTIVITY PURISTS

You’d like optimal traction, more power to the ground, and enhanced operator comfort? The 6R features TLS Plus front axle suspension, HCS Plus cab suspension and Variable Ratio Steering for less steering effort.

6R HYDRAULICS: SMART MUSCLE

Definitely located at the upper end of the performance spectrum, the hydraulic pump of the 6230R and 6250R delivers an impressive flow of 160 l/min at only 1,500 RPM.

New for the 6145R and the 6155R is the 155 l/min pump that will increase the performance in demanding hydraulic operation.

Smart control

The intuitive CommandCenter controls allow you to manage the Selective Control Vales (SCVs) on the move. The large digital display lets you monitor flow rates and times, keeping you in control of all hydraulic systems.

SCVS APLENTY

In a 6R you get up to six electro-hydraulic selective control valves (SCVs) – with pressure relief lever, logically Clustered.

6110R - 6120R - 6130R

AutoPowr delivers step-less power at speeds between 50 m/h and 50 km/h. Once running at maximum road speed, engine rpm automatically drops to the minimum level required to maintain that speed, reducing noise and saving fuel. 50 km/h is maintained at 1630 rpm, 40 km/h at 1300 rpm with CommandPRO.

6135R - 6145R - 6155R

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

6175R - 6195R - 6215R

AutoPowr delivers 100% mechanical power at the following most common working speeds. In fact, AutoPower is always using more than 60% of the available mechanical power.

6230R - 6250R

DirectDrive is an eight-speed, three-range transmission. Super-efficient dual-clutch technology always has the next gear lined up, so there’s no lost momentum when shifting. During transport, DirectDrive reduces the engine speed to 1,550 rpm at 40 km/h and 1,600 rpm at 50 km/h, thus reducing fuel consumption. In addition, the AutoClutch function enables you to stop the tractor without pressing the clutch.

HARVEST PROMISE

BACK-UP WHEN YOU NEED IT. GUARANTEED

EXPERT CHECK

The Expert Check optimises your combine ready for the next harvest season. Our specially trained and certified Inspection Experts know which components require special attention – thanks to John Deere’s sophisticated tools developed from knowledge gathered from thousands of harvests.

24 HOUR PARTS PROMISE

We’ve invested in the biggest parts logistics network in the agriculture business. And with more machines in the field than any other manufacturer we hold more parts stock than anyone else. It all means we consistently deliver more than 97% of all orders within 24 hours.

BACK-UP MACHINE

We will provide a back-up machine if parts are delivered late. The difference is that we’ll take care of everything, not just pay a contractor. Our dealers have the right combines with the right size in reserve.

TRAINING

Factory trained experts at Certified dealers will provide professional driving training not just when you take delivery of your new combine, but they will be on-hand for refresher courses season after season.

EXPERTS IN PLACE

Certified dealers have full-time, factory trained harvesting experts to set up your combine prior to the season. They’ll also visit you during the season to make sure your machine is always running at the optimum performance level.

*Eligible are all John Deere combines max. 7 years old, maintained in line with operator’s manual utilizing genuine parts only and EXPERT CHECK after season assessment with carried out subsequent repair work as recommended.